If your company does a lot of printing, it’s in your best interest to learn about the advantages of flexography. Flexography is a type of direct rotary printing that boasts many advantages over conventional printing techniques. Flexography is excellent for printing large volumes of materials and works well on any surface. This list explains the six biggest benefits of flexographic printing:

1. Flexography is compatible with many different inks.

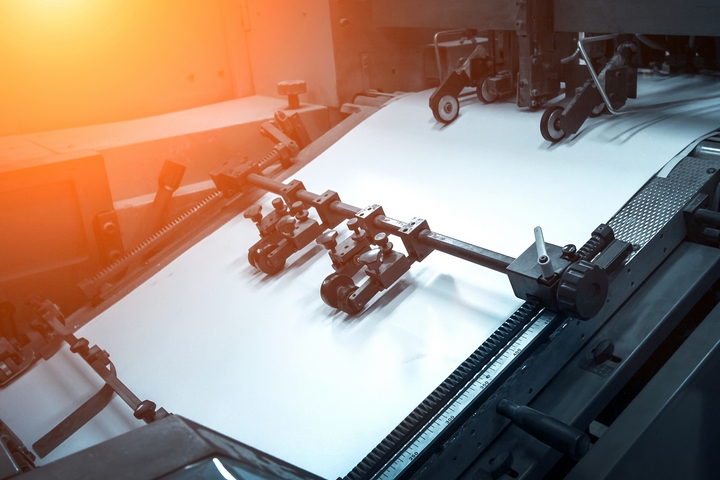

Flexography is a variation of direct rotary printing. Flexography involves impressing a raised image onto a flexible surface, which allows the picture to be “stamped” onto a variety of materials. Flexography is a versatile way of handling large-scale reproduction of images and text.

Flexography is compatible with a variety of different inks and can be used on both porous and non-porous surfaces. Because of its versatility, flexographic printing is a process used for many different consumer and commercial needs.

2. Flexography suits many different surfaces

Unlike other printing techniques, flexography is compatible with many different types of inks including fast drying inks. This versatility makes flexography advantageous for packaging and printing newspapers and similar publications.

Flexographic printing can use water-based, fluorescent and metallic inks in addition to traditional solvent-based inks for printing. Flexography is widely used for printing labels on disposable cups, shopping bags, wallpaper and milk cartons.

3. Flexography has faster production speed over other printing techniques

Using a flexographic printing press significantly cuts down your press setup time. When compared to gravure or lithographic printing, flexography is ready in a much shorter amount of time. As previously mentioned, flexography can also use fast drying inks which again speeds up production. In case you need to use water-based ink, the cleanup process is much easier and quicker with flexography.

After you set up your flexographic printing press and flex storage solutions, you can also integrate laminating, die cutting and many other finishing stations down the line. Flexography is known for its ability to keep production continuous which makes it an excellent choice for high volume work.

4. Flexographic printing is cheaper to use.

Because production, cleanup, and setup times are much faster with flexographic printing, it contributes to reducing your overall costs. An advantage of flexographic printing presses is that they increase your return on investment by creating more sellable output, while simultaneously reducing operating costs. Your clients also benefit from this since products are cheaper without compromising on quality.

The relief plate used in flexography can last for a few million of impressions before needing replacement. Not only do the plates last longer, but they’re also cheap to replace. Since there are also fewer steps in the flexography printing process, you also save money on labor costs.

5. Flexography is excellent for solid colour printing.

One of the most significant advantages of flexographic printing is being able to print solid colors on porous and non-porous surfaces. Other printing techniques require several layers of ink in order to attain the proper saturation and richness. The ink used in flexography can quickly dry and cure which allows for several layers to be put on at a time. Not only is this faster, but also you save more paint and get a better final product.

6. Flexographic printing is easy on the environment.

A flexographic printing advantage is that it reduces your reliance on platemaking solutions, solvents based inks and cleaning materials that contain harmful chemicals. The printing industry as a whole is usually under scrutiny for its effects on the environment and flexography provides a more sustainable solution.

Flexographic printing can use solvent free inks, which reduces volatile organic chemical emissions. Most flexographic presses also come with mechanisms that recycle wasted ink and minimize waste. Flexography is one of the most environmentally friendly mass printing techniques we have available.